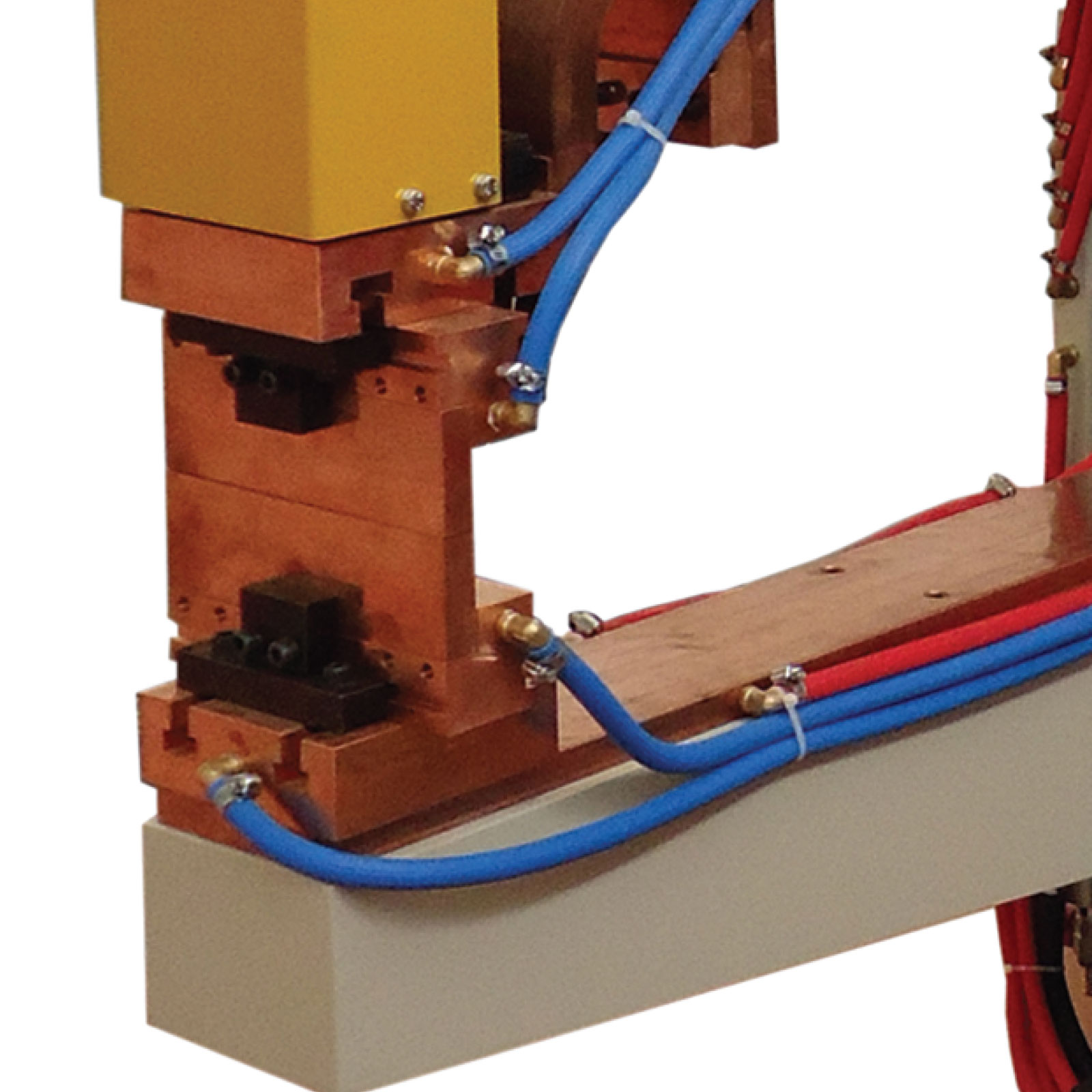

A projection-type spot welding machine is designed specifically for projection welding, which is a variation of resistance welding. In projection welding, metal sheets are joined using localized heat and pressure applied to specific contact points or projections on the work piece, rather than a continuous line or area. This method allows for more precise welds and is ideal for welding thicker materials or attaching components with small, raised projections (like bolts or nuts) to flat metal sheets.

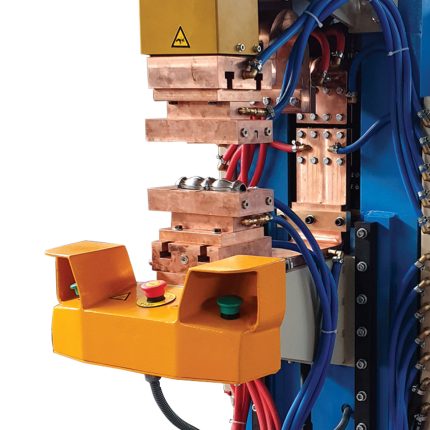

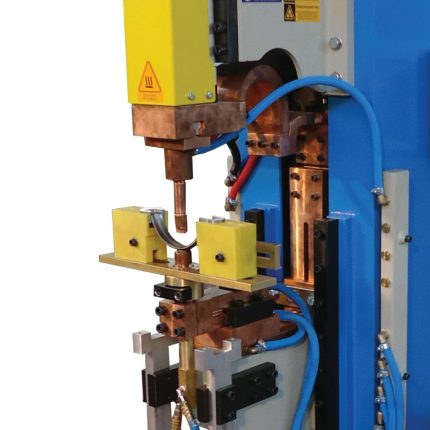

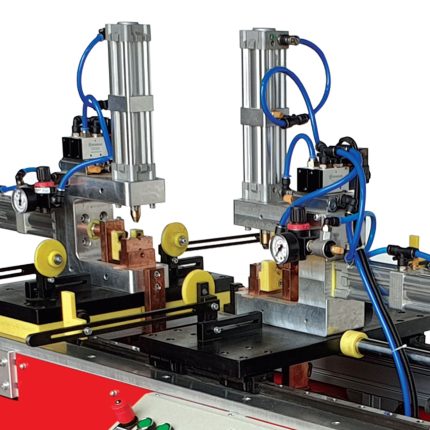

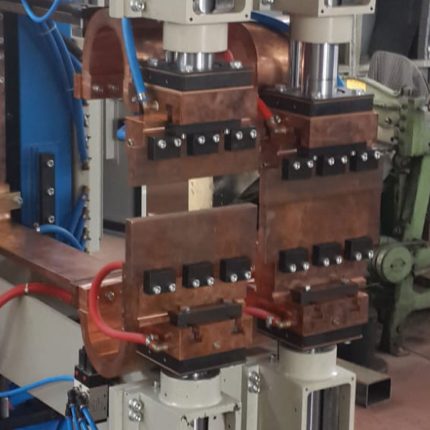

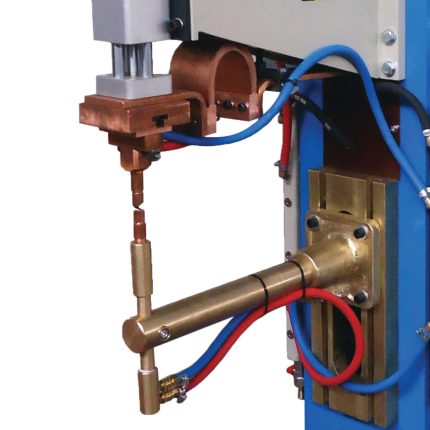

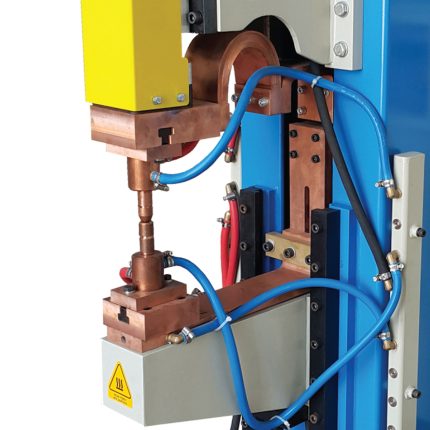

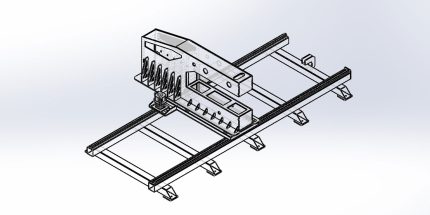

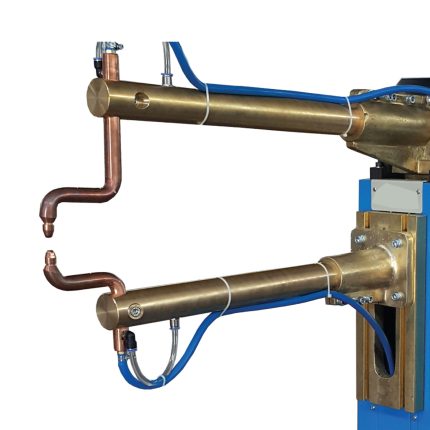

SWA120 / AXE TYPE ALDE SPOT WELDING MACHINE

A projection-type spot welding machine is designed specifically for projection welding, which is a variation of resistance welding. In projection welding, metal sheets are joined using localized heat and pressure applied to specific contact points or projections on the work piece, rather than a continuous line or area. This method allows for more precise welds and is ideal for welding thicker materials or attaching components with small, raised projections (like bolts or nuts) to flat metal sheets.

| Rated Power | 120 KVA |

| Continuons Power | 85 KVA |

| Primar Voltage | 400 V |

| Frequency | 50-60 Hz |

| Secondery Voltage | 7 – 8,5 V |

| Fuse | 250 A |

| Secondery Short Circuit Current | 32 KA |

| Number of Stages | 1 |

| Stroke | 100 mm |

| Elektode Force | 100 – 620 Kg |

| Air Presure | 3 – 8 Bar |

| Arm Lenght | 360 – 800 mm |

| Cooling Water Ressure | 5 Bar |

| Flow Rate of Cooling Water | 6 lt / dk. |

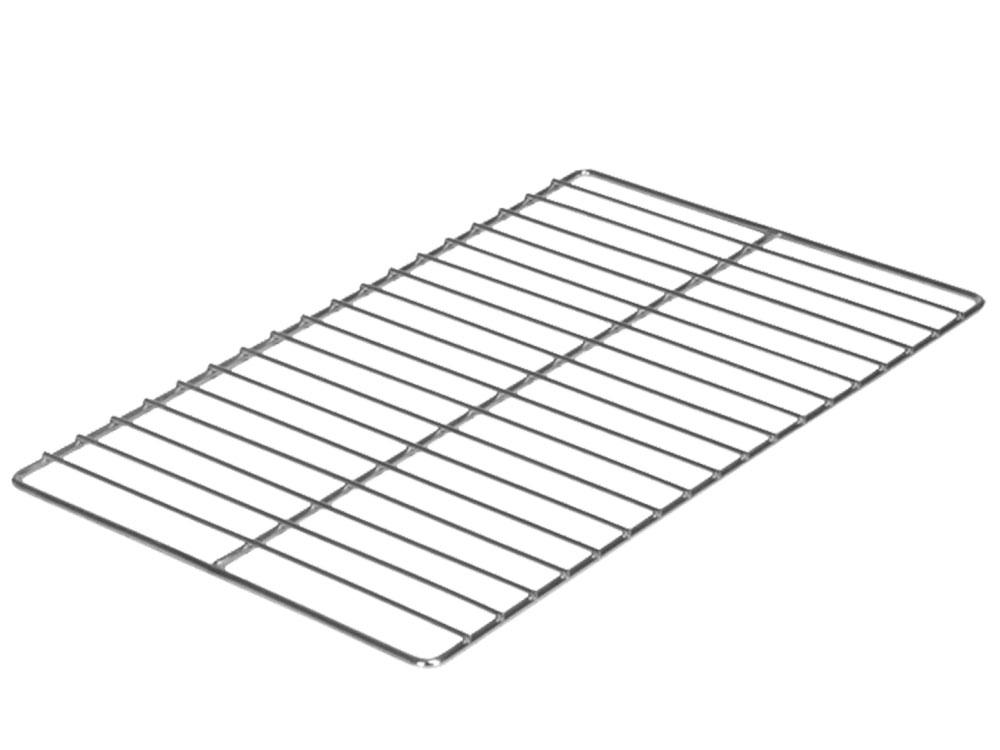

| Welding Capacity For Mid Steel | 14 mm + 14 mm |

| Welding Capacity For Stainless Steel | 10 mm + 10 mm |

Description

Product information request form