A resistance seam welding machine is used to create continuous, leak-proof welds along the seams of overlapping or abutted metal sheets. This process is similar to spot welding, but instead of individual welds, it produces a series of overlapping weld nuggets, forming a continuous, airtight, and watertight joint. Seam welding is ideal for applications where a fluid-tight bond is needed, such as fuel tanks and food cans.

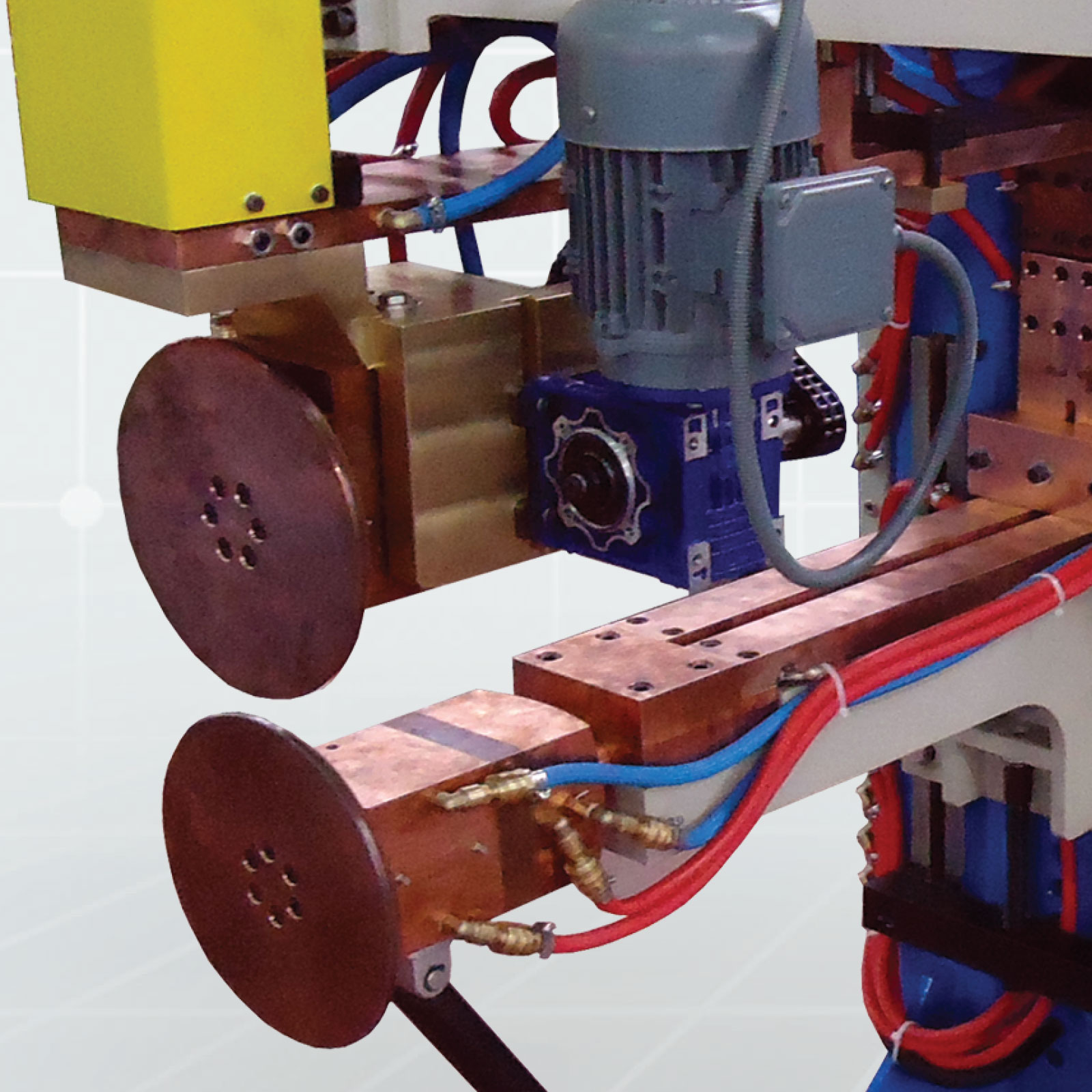

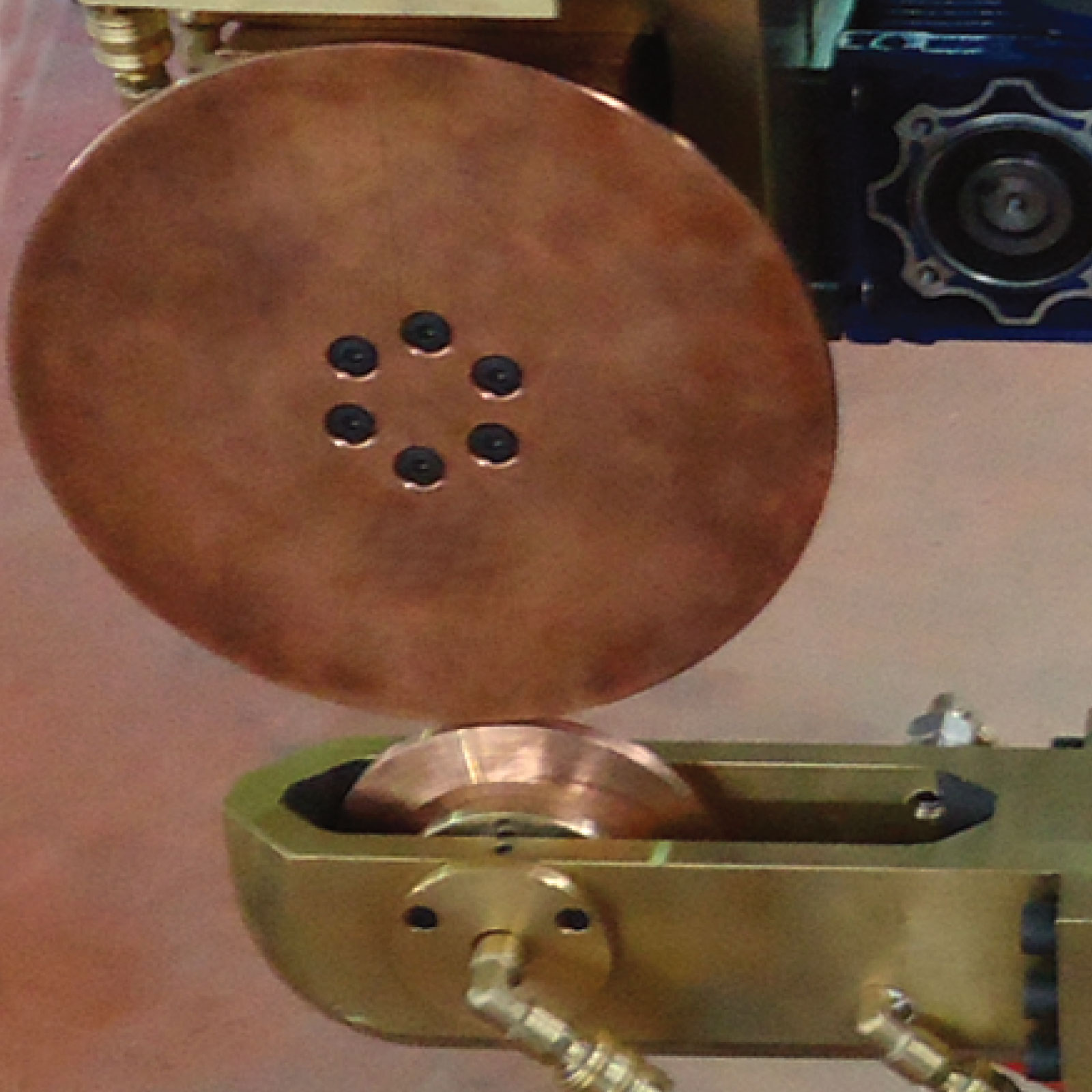

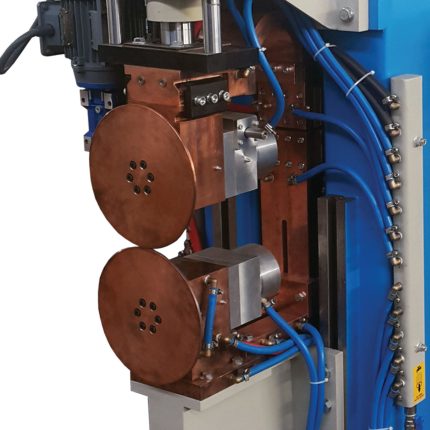

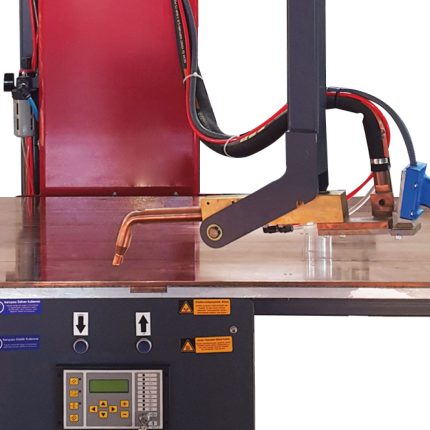

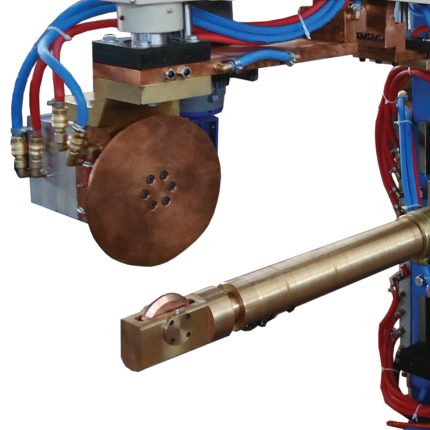

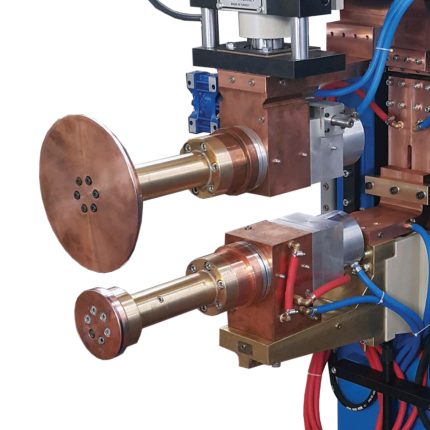

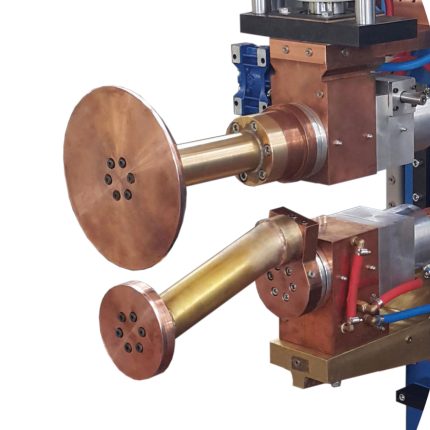

SWB120 / SEAM WELDING MACHINE FOR VERTICAL AND HORIZONTAL USE

A resistance seam welding machine is used to create continuous, leak-proof welds along the seams of overlapping or abutted metal sheets. This process is similar to spot welding, but instead of individual welds, it produces a series of overlapping weld nuggets, forming a continuous, airtight, and watertight joint. Seam welding is ideal for applications where a fluid-tight bond is needed, such as fuel tanks and food cans.

| Rated Power | 120 KVA |

| Continuons Power | 85 KVA |

| Primar Voltage | 400 V |

| Frequency | 50-60 Hz |

| Secondery Voltage | 7 – 8,5 V |

| Fuse | 250 A |

| Secondery Short Circuit Current | 32 KA |

| Number of Stages | 1 |

| Stroke | 100 mm |

| Elektode Force | 235-630 Kg |

| Air Presure | 3 – 8 Bar |

| Arm Lenght | 2,5 m |

| Cooling Water Ressure | 5 Bar |

| Flow Rate of Cooling Water | 6 lt / dk. |

| Welding Capacity For Mid Steel | 3 mm + 3 mm |

| Welding Capacity For Stainless Steel | 2 mm + 2 mm |

Category: Alde Rezistance Seam Welding Machines

Description

Product information request form