A resistance butt welding machine is a type of resistance welding equipment used to join two metal workpieces end-to-end, often used for welding rods, wires, or tubes. In this method, heat generated by electric resistance at the joint fuses the materials while applying axial force, forming a strong bond.

Components and Features

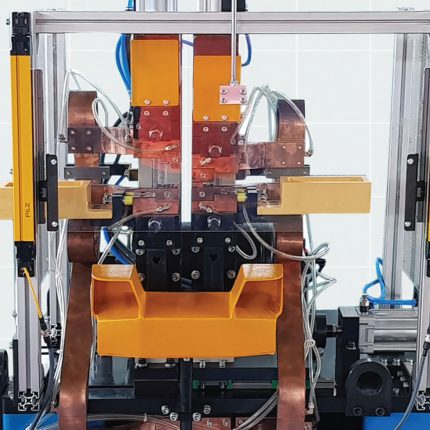

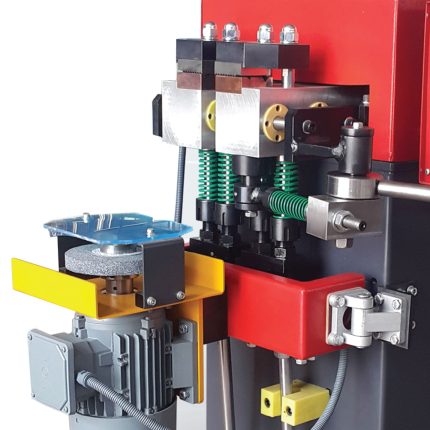

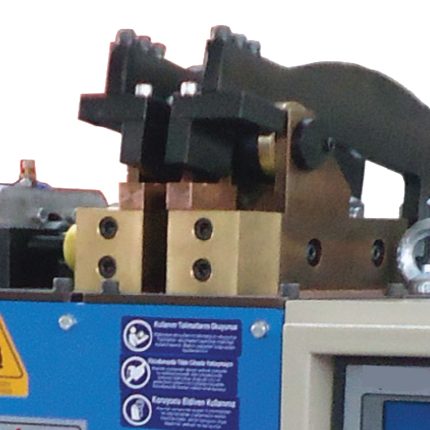

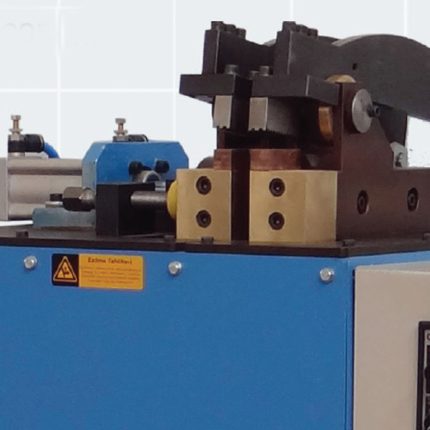

1. **Electrodes or Clamps**: The machine holds the two ends of the workpieces together with electrodes or clamps that conduct electricity and apply force.

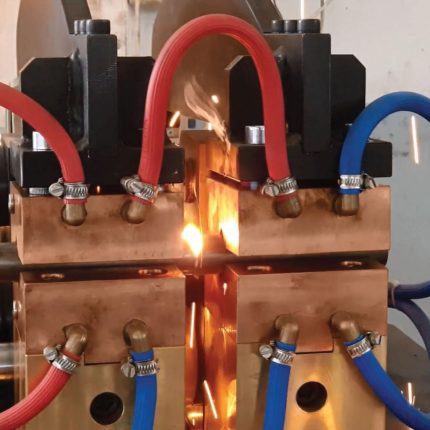

2. **Welding Transformer**: Supplies controlled electrical current, generating heat at the interface of the workpieces.

3. **Axial Force Application System**: Hydraulic or pneumatic systems apply force along the axis of the workpieces, ensuring proper fusion at the joint.

4. **Control System**: Allows precise control over current, force, and weld time for a consistent joint quality.

Process Types

There are two main types of resistance butt welding:

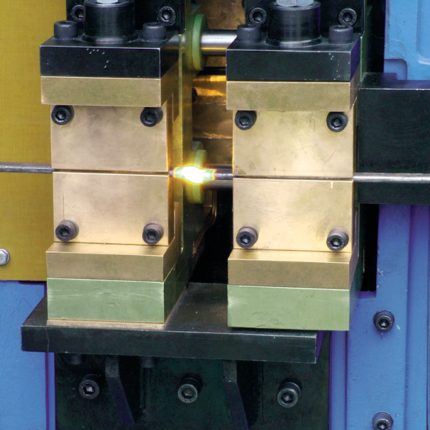

- **Continuous Resistance Butt Welding**: Generates heat with continuous current while applying force, ideal for longer joints.

- **Flash Welding**: Uses short bursts of high current to create a series of small “flashes” or sparks, melting the ends just before they are pressed together.

Benefits

- **Strong, Consistent Joints**: Achieves durable connections with minimal material waste.

- **Minimal Filler Materials**: Unlike other welding types, butt welding doesn't typically require additional filler material, making it cost-effective.

- **Efficient and Clean Process**: Produces minimal smoke and debris, resulting in a cleaner process compared to arc welding methods.

Application

Resistance butt welding machines are commonly used in industries that require high-strength joints and precise alignment, such as:

- **Automotive Parts** (axles, drive shafts)

- **Railway Components**

- **Wire and Cable Manufacturing**

- **Steel and Aluminum Pipe Welding**

Would you like to explore specific machine models, manufacturers, or control options for resistance butt welding?