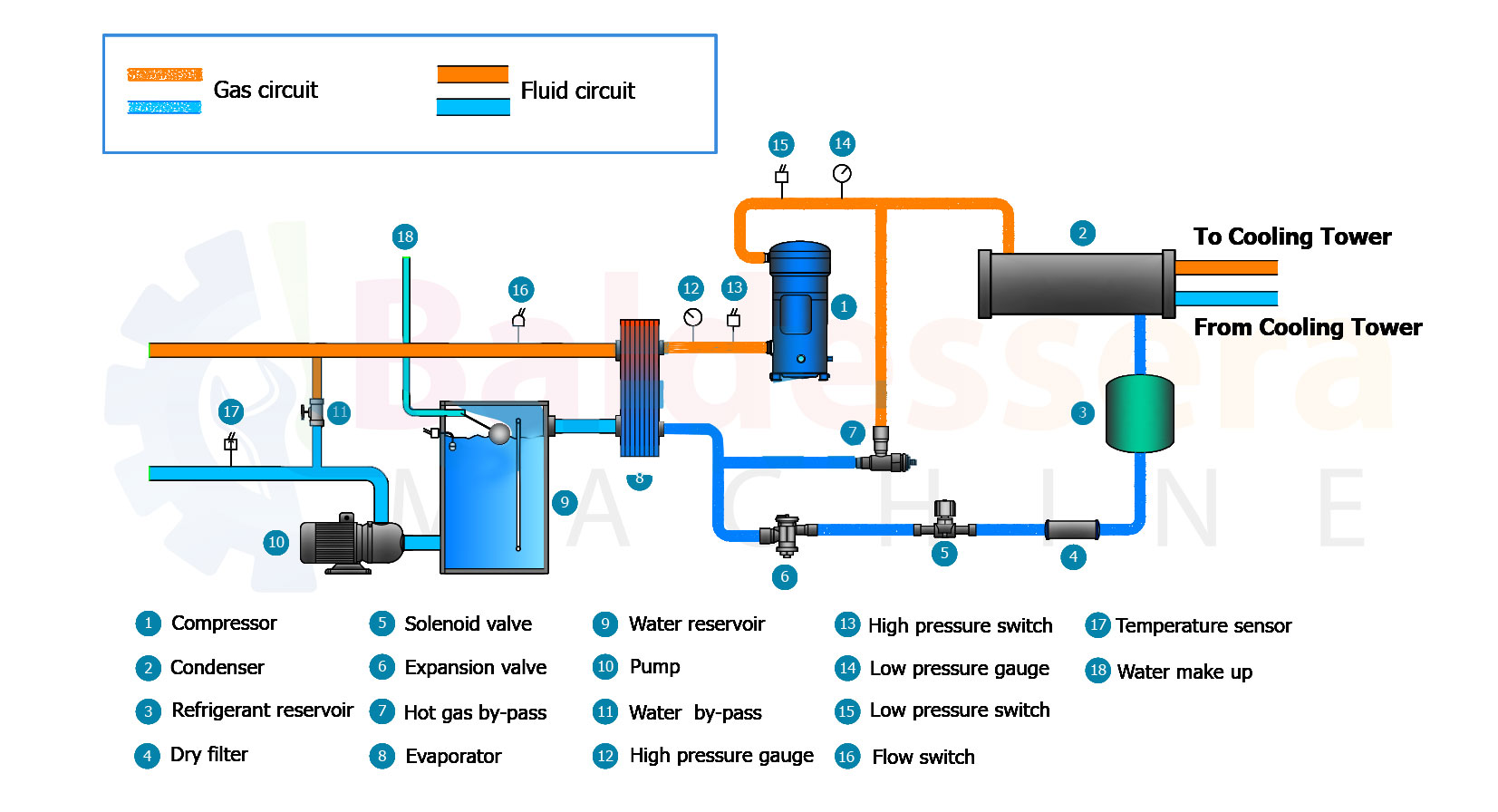

1. **Cooling Capacity**: Chillers are rated based on their cooling capacity, typically measured in BTU or kilowatts, to match the heat load of the welding machine.

2. **Temperature Control**: Many chillers come with thermostatic controls to maintain a specific temperature range, ensuring efficient cooling.

3. **Flow Rate**: A suitable flow rate is crucial for effective cooling. Chillers should be capable of circulating water at a rate sufficient to keep the machine cool.

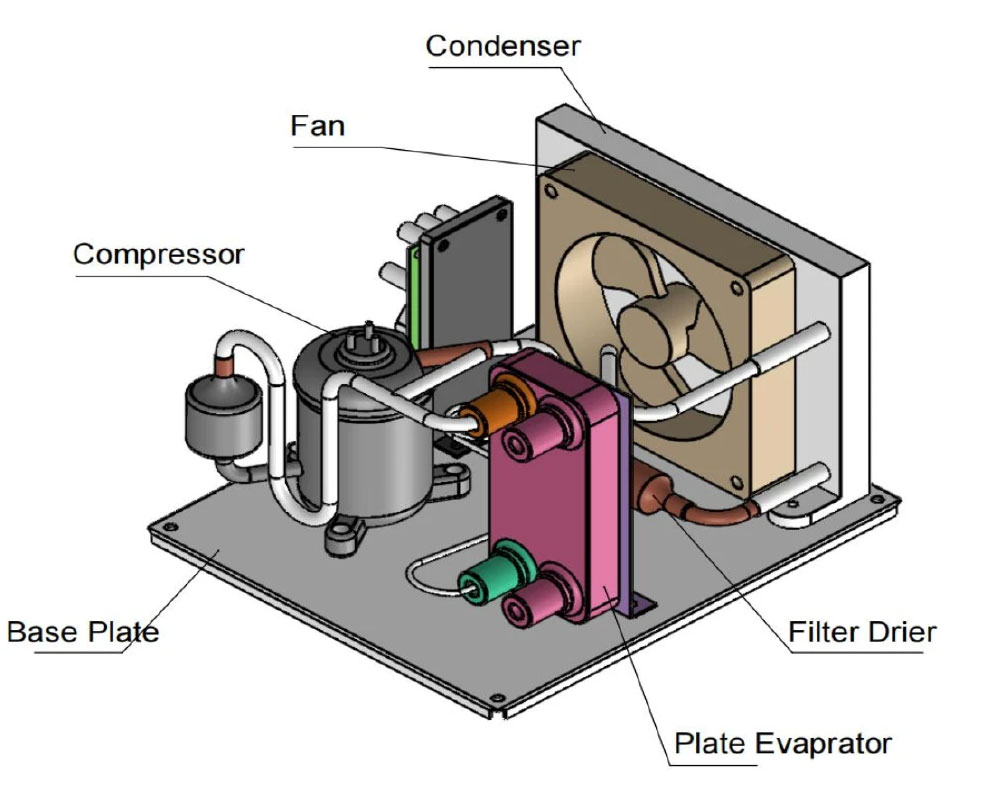

4. **Compact Design**: Many modern chillers are designed to be space-efficient, fitting easily into production environments.

5. **Durability**: Built to withstand industrial environments, these chillers are often made from corrosion-resistant materials.

Benefits

- **Extended Equipment Life**: By maintaining optimal temperatures, chillers help prolong the life of welding machines and components.

- **Improved Weld Quality**: Consistent cooling ensures stable temperatures, leading to better weld quality and consistency.

- **Reduced Downtime**: Effective cooling minimizes the risk of overheating, reducing the need for maintenance and downtime.

Applications

- **Manufacturing**: Used in various industries, including automotive and electronics, where spot welding is prevalent.

- **Heavy-Duty Welding**: Essential for high-volume or heavy-duty welding applications that generate significant heat.

Considerations for Selection

1. **Compatibility**: Ensure the chiller is compatible with the specific spot welding machine in terms of connections and cooling requirements.

2. **Ambient Conditions**: Consider the environment where the chiller will be located, including temperature and humidity levels.

3. **Maintenance Requirements**: Look for chillers with

easy access for maintenance and service.

If you need more detailed information or

recommendations on specific models,

feel free to ask!