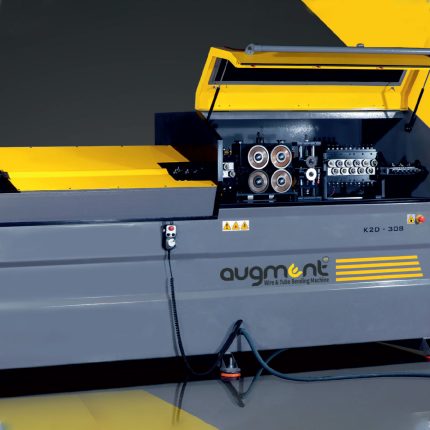

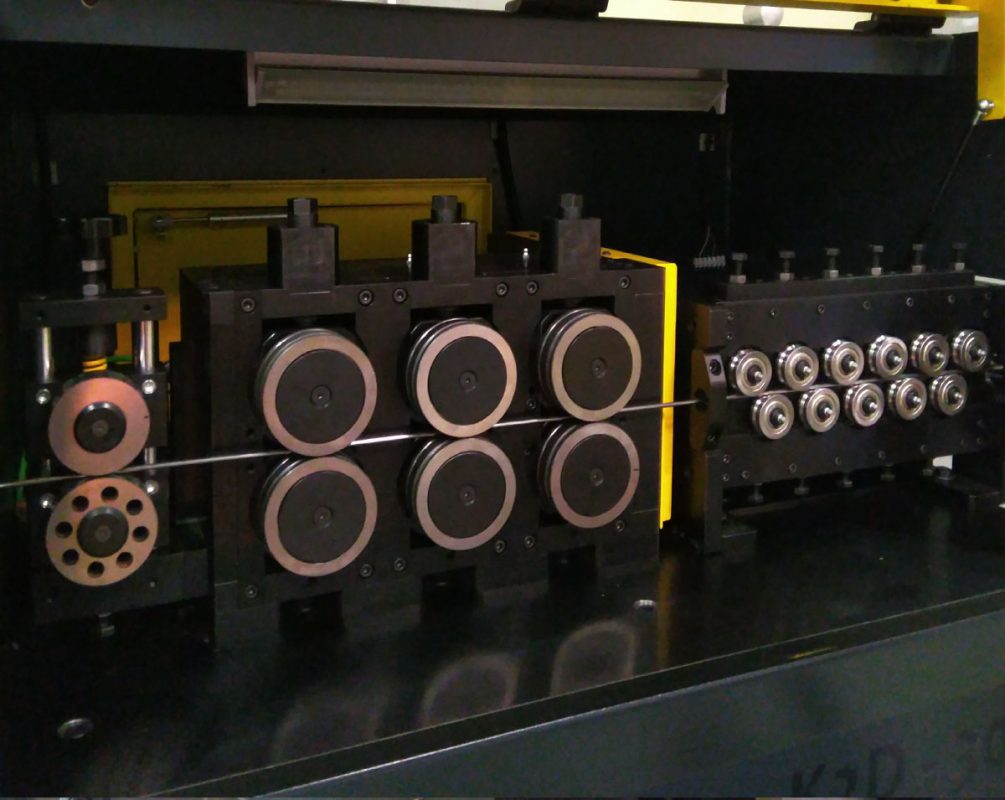

1. **Automation**: Many wire bending machines are automated, allowing for precise and repeatable bends without manual intervention. This increases efficiency and reduces labor costs.

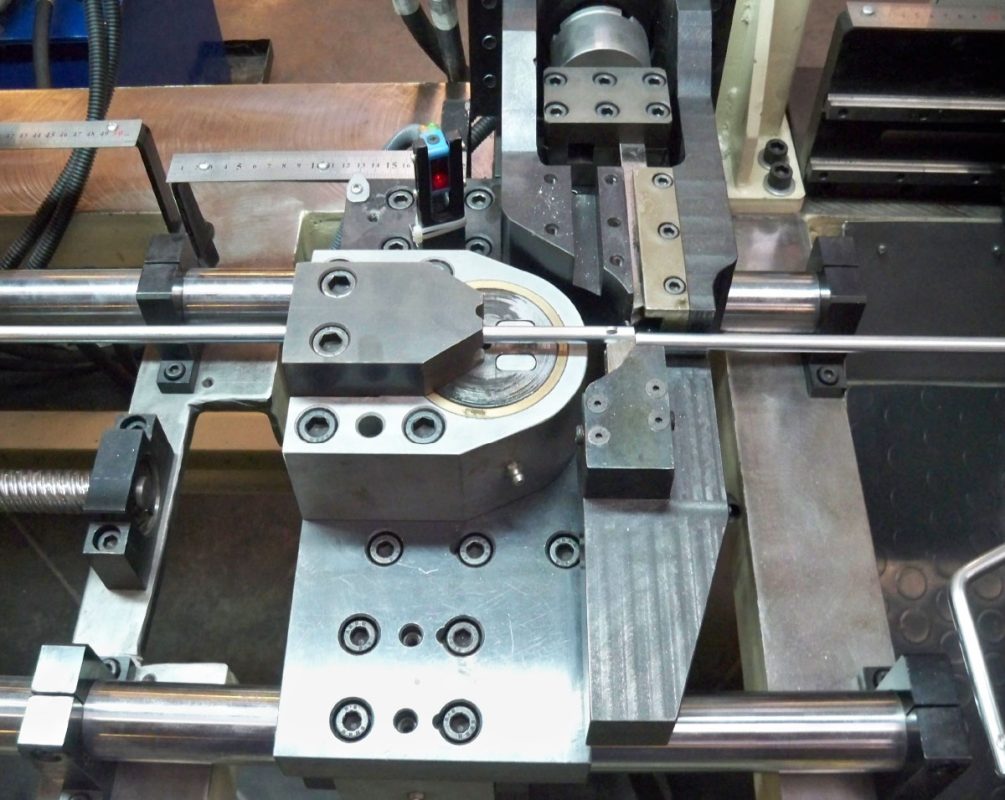

2. **Programmable Controls**: Advanced machines come with programmable logic controllers (PLCs) that enable users to input specific bending parameters, creating complex shapes and designs.

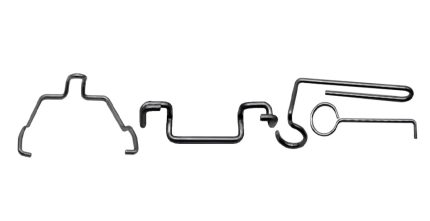

3. **Versatility**: These machines can often handle a range of wire diameters and materials, making them suitable for various projects.

4. **Speed and Efficiency**: Wire bending machines can operate at high speeds, allowing for quick production times, especially in high-volume settings.

Types of Wire Bending Machines

1. **CNC Wire Bending Machines**: Utilize computer numerical control (CNC) for high precision and complex shapes. They are ideal for custom and intricate designs.

2. **Manual Wire Bending Machines**: Require manual operation, suitable for smaller projects or less complex bends.

3. **Semi-Automatic Machines**: Combine manual operation with some automated features, providing a balance between control and efficiency.!

Applications

- **Manufacturing**: Used to create components for furniture, automotive parts, and appliances.

- **Construction**: Bending rebar or wire mesh for reinforcement in concrete structures.

- **Art and Design**: Crafting decorative items or custom metal artworks.

Benefits

- **Precision**: Offers high accuracy in bending, which is essential for quality control.

- **Time-Saving**: Reduces the time required to produce bent wire components.

- **Cost-Effective**: Increases production efficiency, leading to lower costs in the long run.

If you need more specific information about types, brands, or features, just let me know