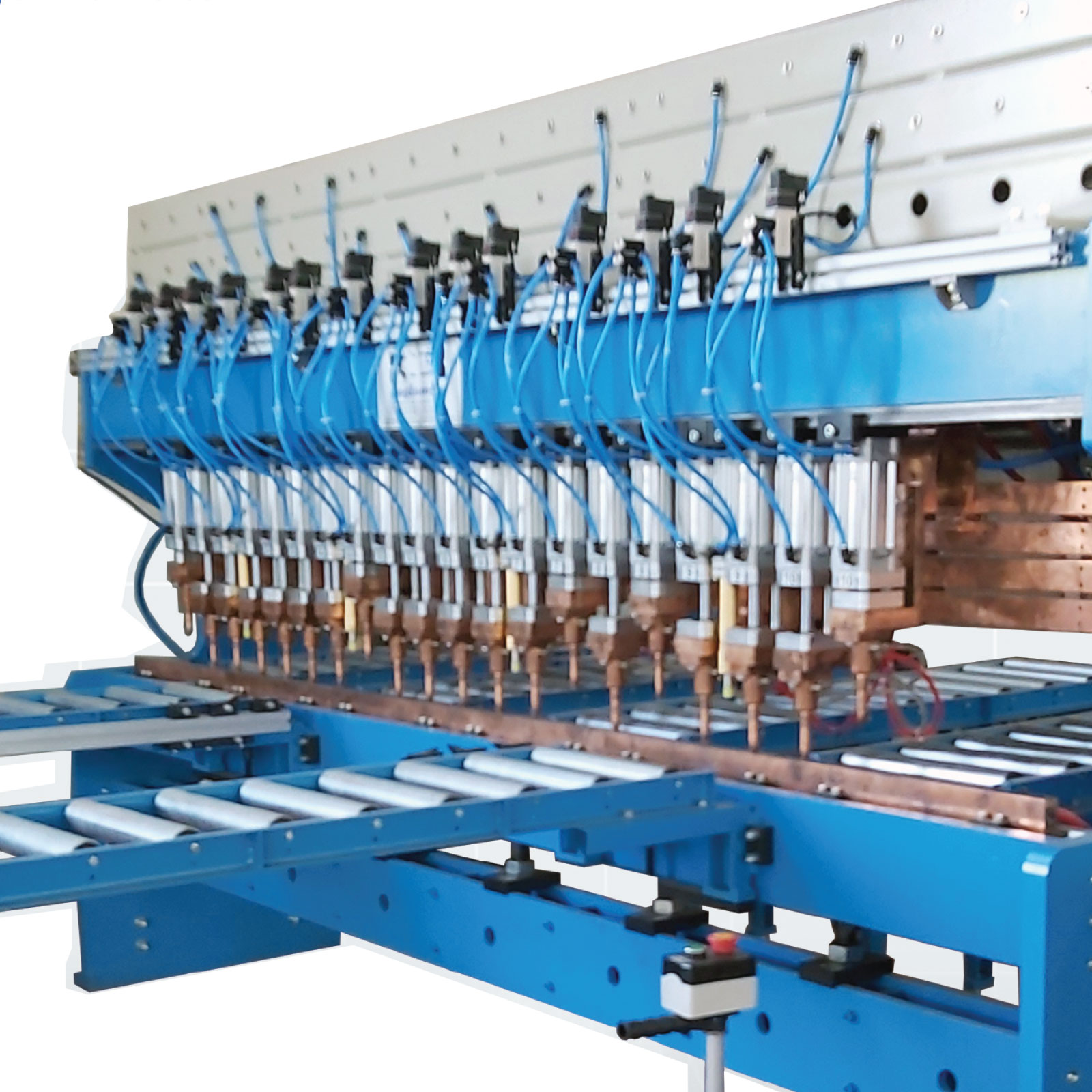

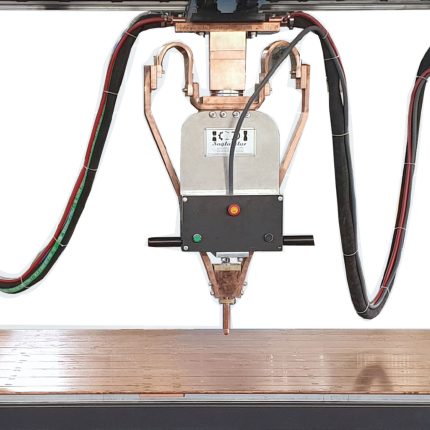

A multiple piston spot welding machine is a type of spot welding equipment designed to perform multiple welds simultaneously or in rapid succession. This is achieved by using several pistons, each with its own electrode, arranged in a single unit to handle a variety of welding points on a workpiece without needing to reposition it. Such machines are ideal for high-volume production environments where efficiency, speed, and consistency are essential, as they can weld multiple spots at once, significantly reducing cycle time.

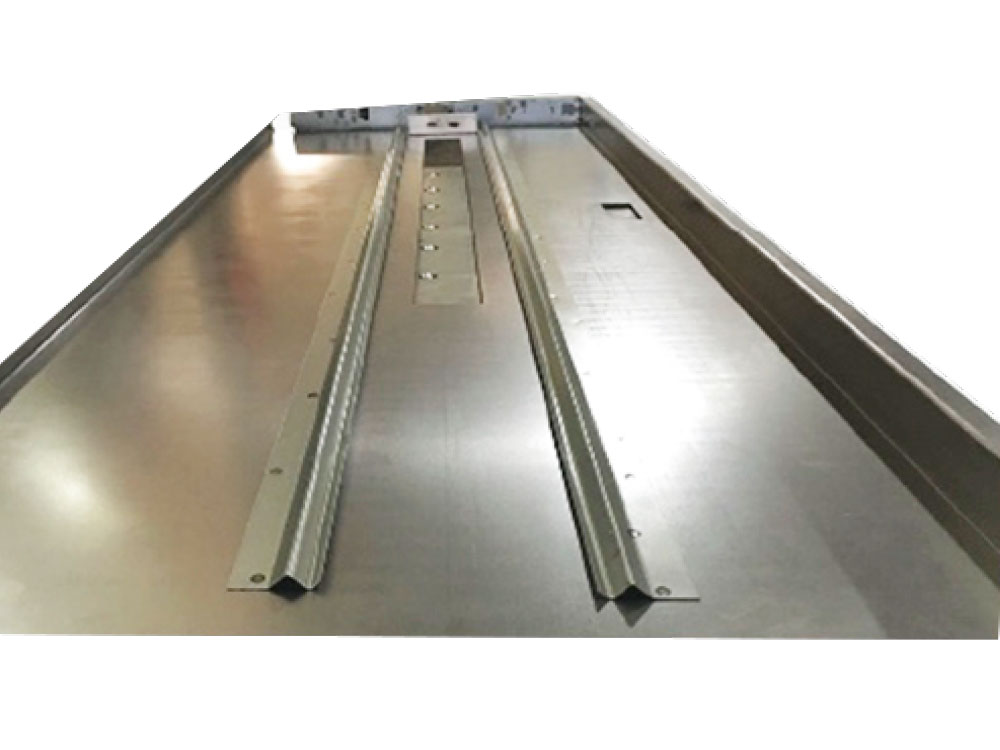

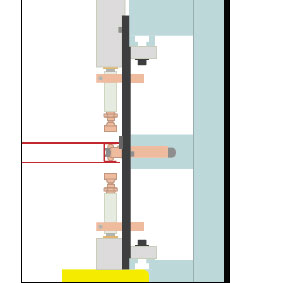

SWMP201 / MULTIPLE PISTON ALDE SPOT WELDING MACHINE FOR DOOR STIFNER WELDING

A multiple piston spot welding machine is a type of spot welding equipment designed to perform multiple welds simultaneously or in rapid succession. This is achieved by using several pistons, each with its own electrode, arranged in a single unit to handle a variety of welding points on a workpiece without needing to reposition it. Such machines are ideal for high-volume production environments where efficiency, speed, and consistency are essential, as they can weld multiple spots at once, significantly reducing cycle time.

| Rated Power | 2×150 KVA |

| Continuons Power | 105 KVA |

| Primar Voltage | 400 V |

| Frequency | 50-60 Hz |

| Secondery Voltage | 7 – 10 V |

| Fuse | 250 A |

| Secondery Short Circuit Current | 38 KA |

| Stroke | 100 mm |

| Number Of Stages | 1 |

| Elektode Force | 100-620 Kg |

| Air Presure | 3 – 6 Bar |

| Welding Per Minute | – |

| Cooling Water Ressure | 5 Bar |

| Flow Rate of Cooling Water | 15 lt / dk. |

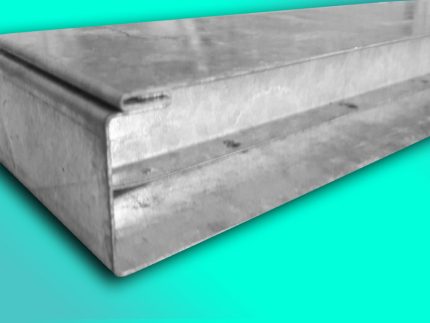

| Welding Capacity For Mid Steel | 4 mm + 4 mm |

| Welding Capacity For Mid Steel | 3 mm + 3 mm |

Description

Product information request form