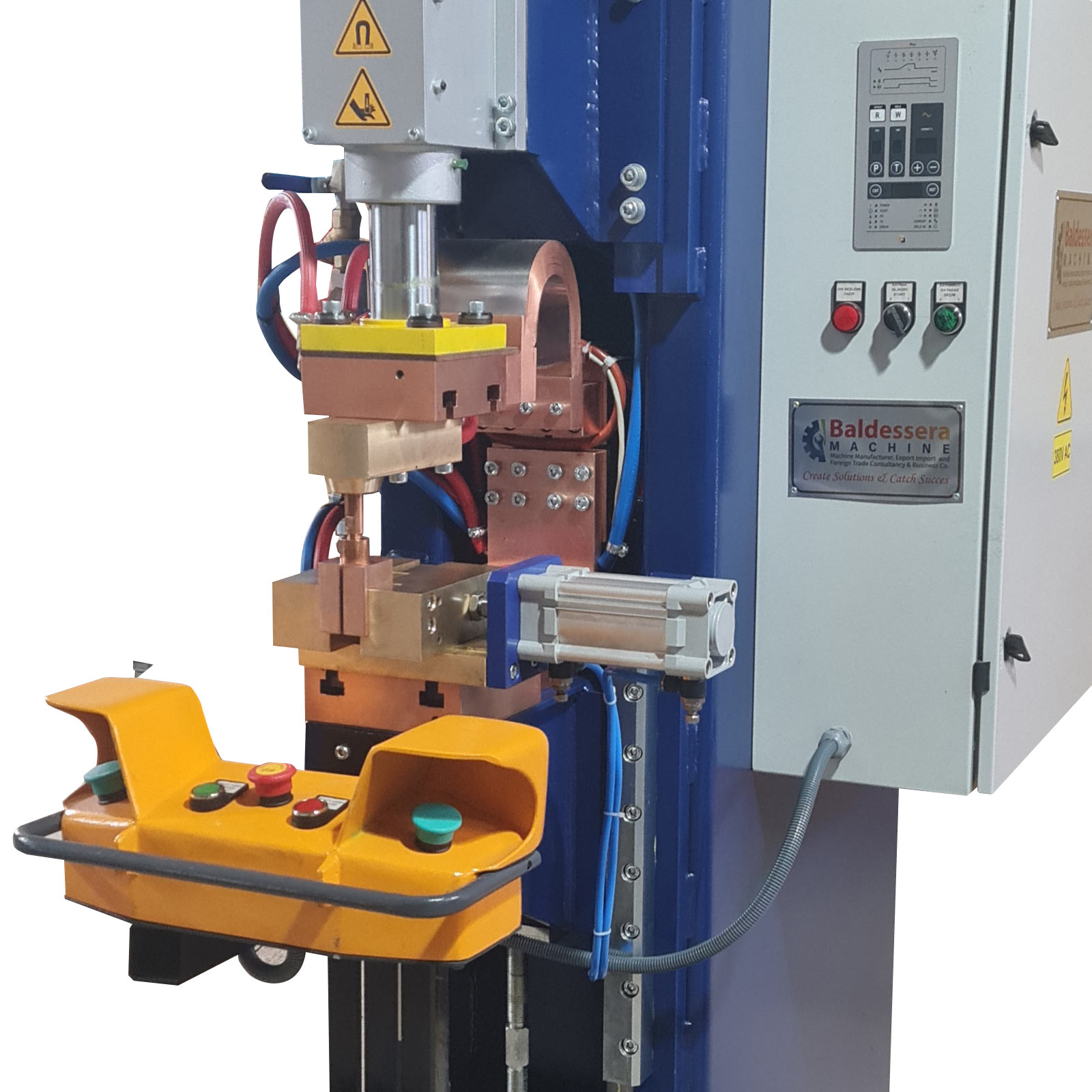

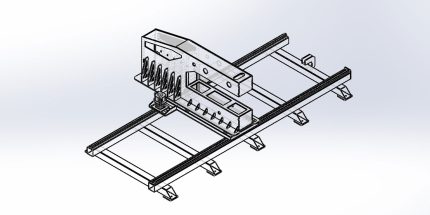

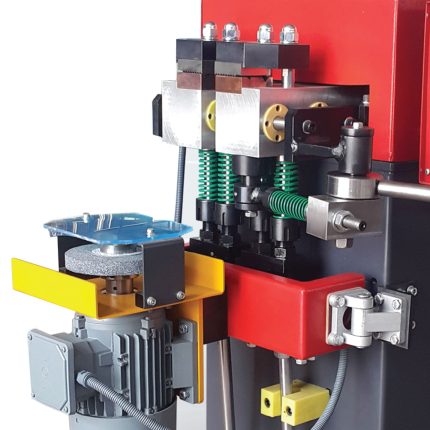

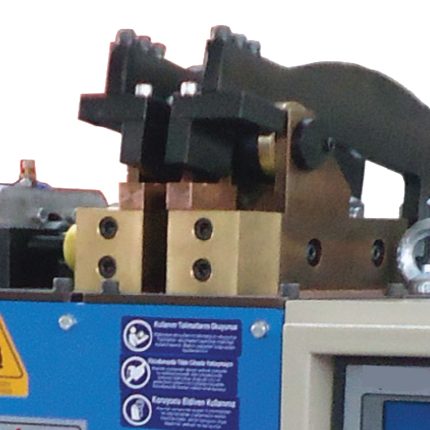

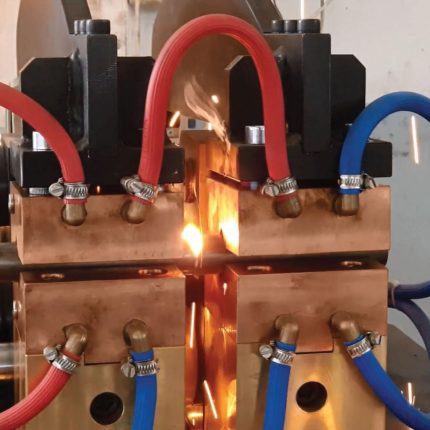

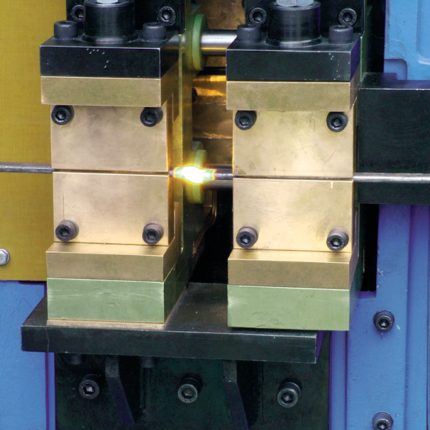

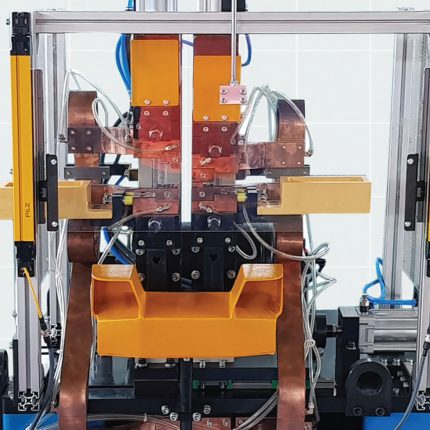

A spot welding machine is a type of resistance welding equipment used to join two or more metal pieces together by applying heat and pressure at specific points, or "spots." The process involves the following key components.

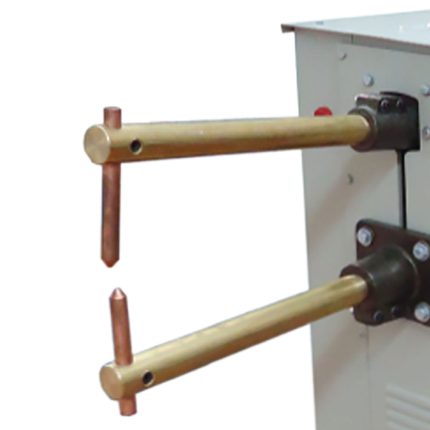

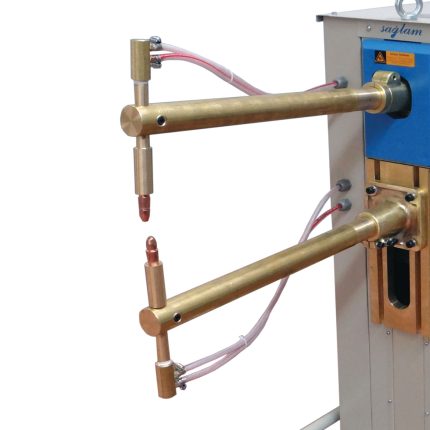

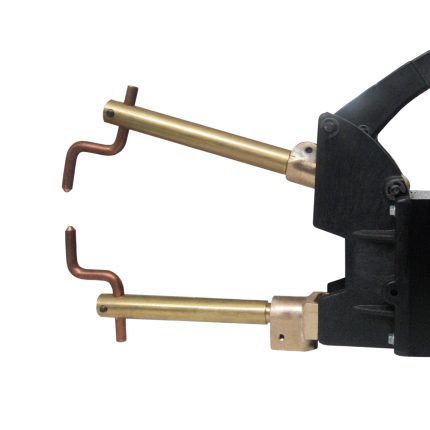

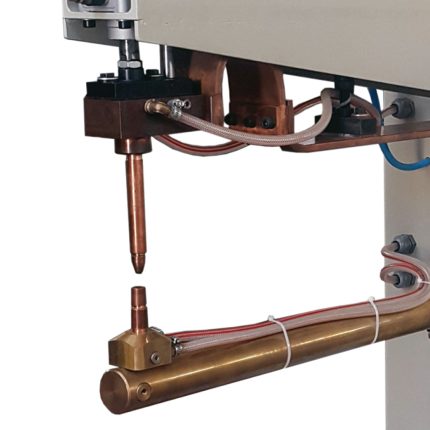

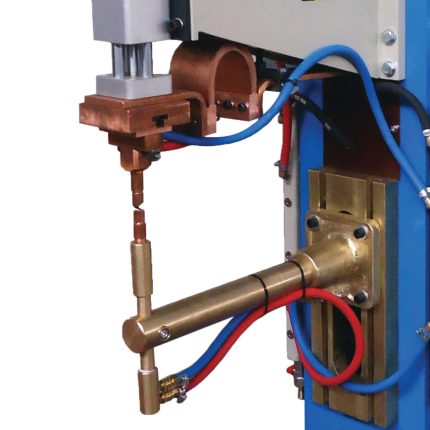

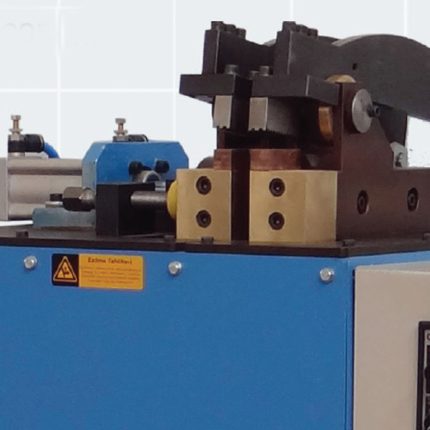

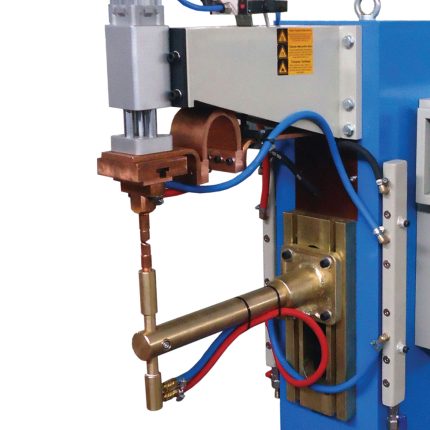

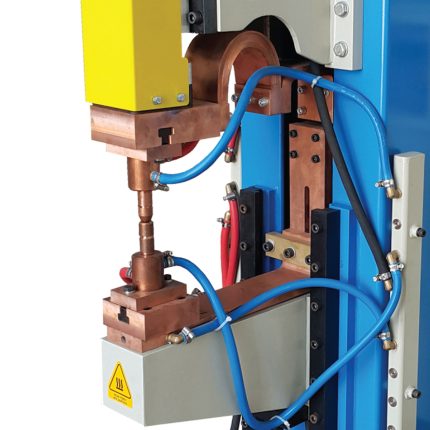

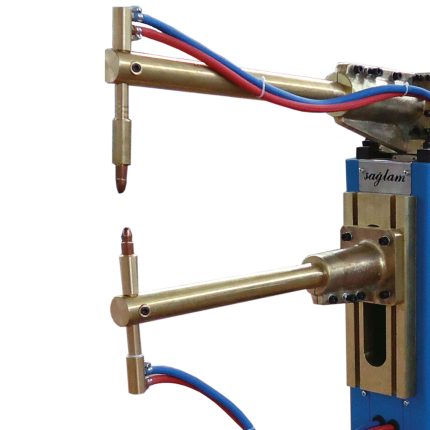

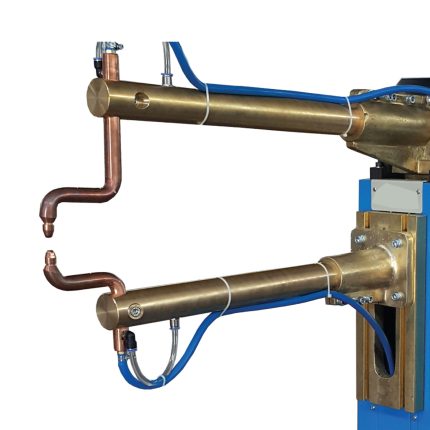

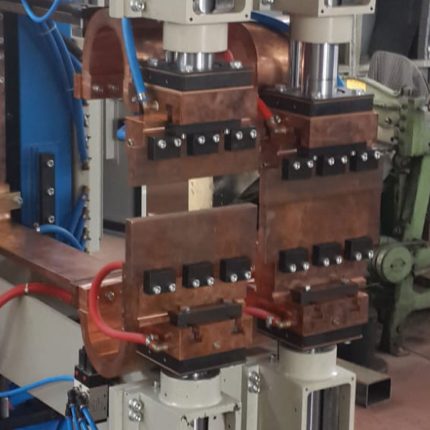

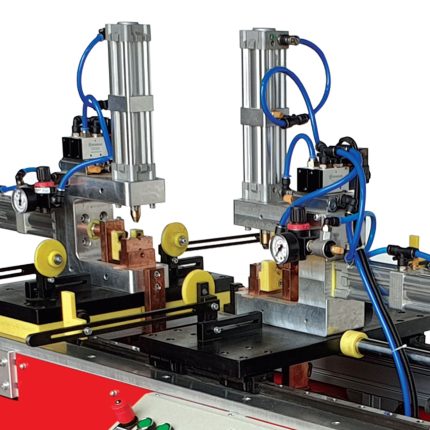

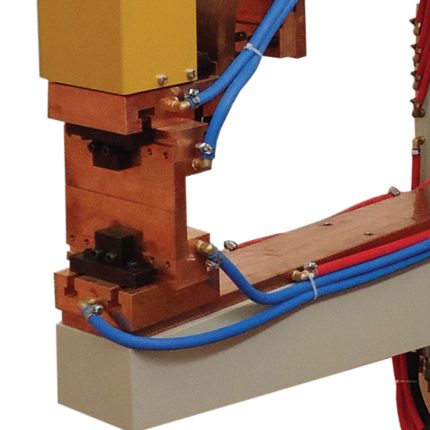

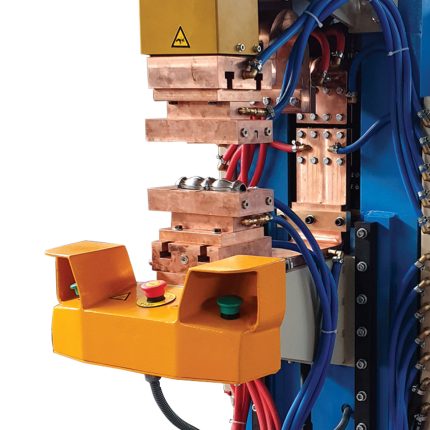

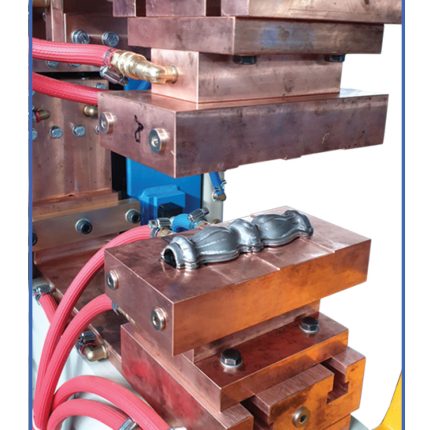

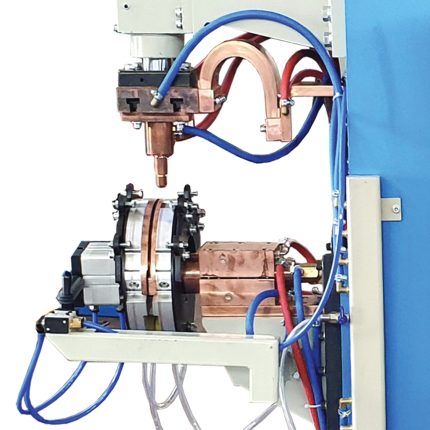

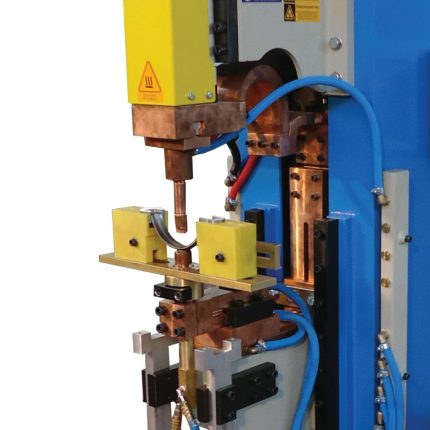

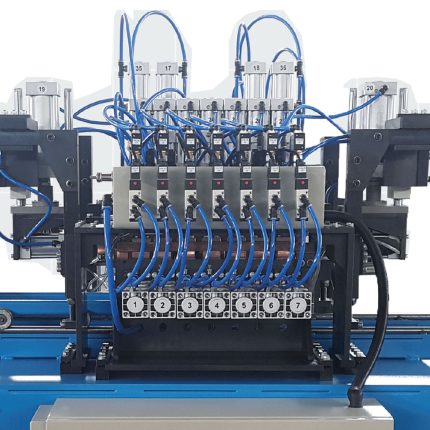

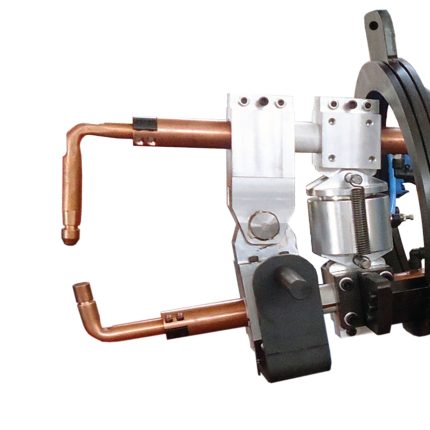

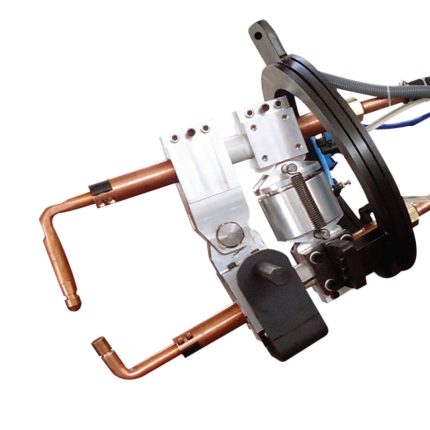

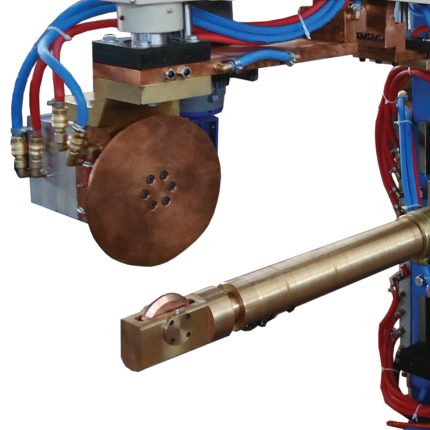

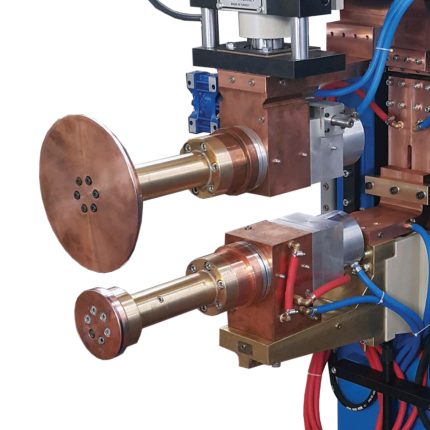

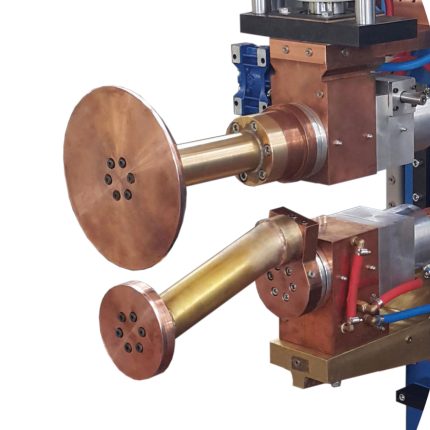

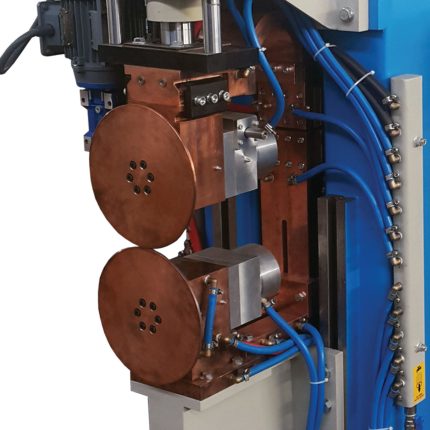

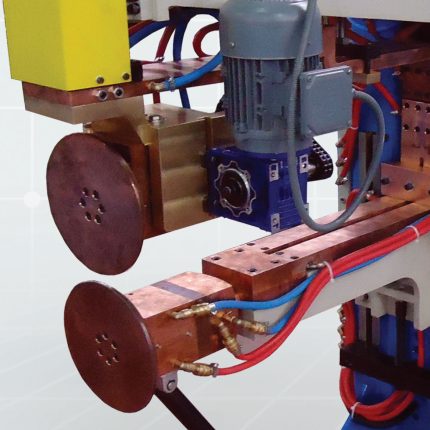

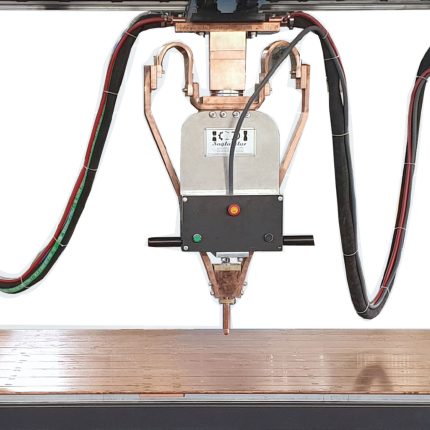

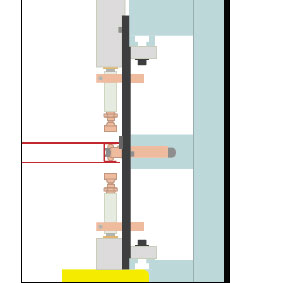

1. **Electrodes**: Copper electrodes deliver the welding current to the workpieces. They apply pressure to hold the pieces together.

2. **Power Supply**: This provides the electrical current necessary for the welding process. The current flows through the metal workpieces, creating resistance and generating heat.

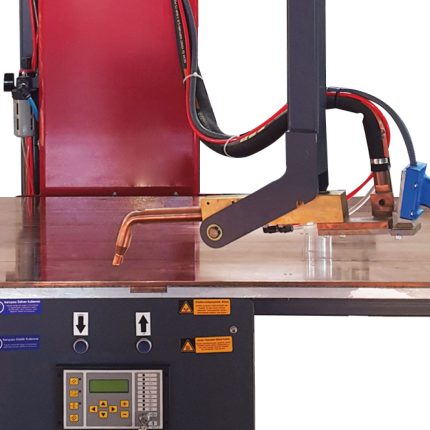

3. **Control System**: This regulates the duration and intensity of the current, ensuring consistent weld quality.

Application

- Automotive manufacturing (e.g., car body assembly)

- Electrical component production

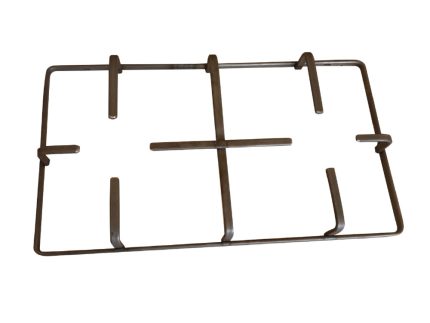

- Appliance manufacturing

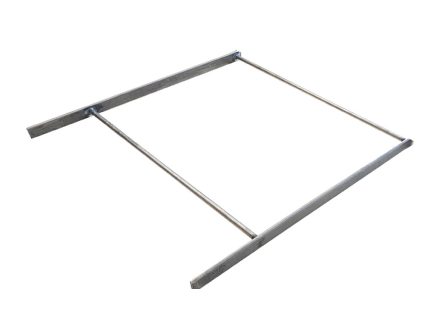

- Sheet metal fabrication

Benefits

- Fast and efficient process

- Minimal distortion of work pieces

- Strong welds with good fatigue resistance

If you have specific questions about spot welding machines or need information on a particular aspect, feel free to ask!