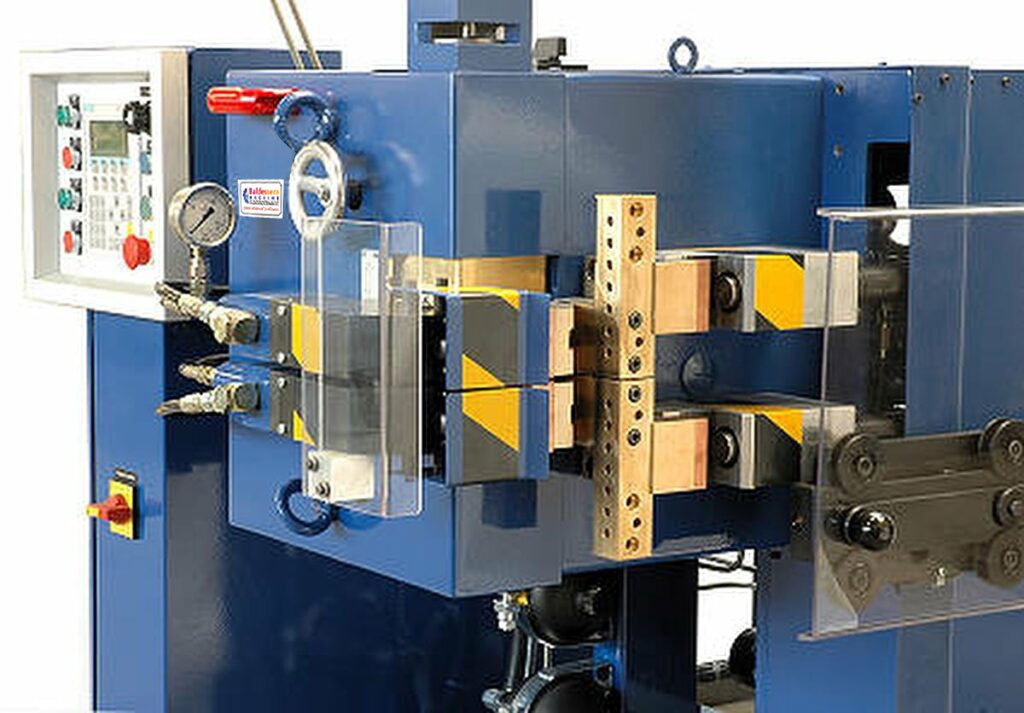

Type BW flash butt welding machines for the highest productivity in the heaviest of industrial use with the highest strength of the joint In order to achieve the highest possible tensile strength and the related fulfilment of the standard requirements, BALDESSERA type BW flash machines are the means of choice. The automated sequence of the welding begins with the preheating of the wire ends followed by the flashing. It is ended with the welding process. Even in the standard version, all type BW machines are equipped with hydraulic clamping devices. The equipment of the type BW machines can be supplemented with different annealing processes (in accordance with the requirements of the material to be processed) and deburring devices, as well as machines and devices for pre- and post-treatment of welds. Benefits of the flash butt welding of steel and aluminium wires with our type BW machines:

• Finest welding quality with metallurgical clean joints; strengths of approx. 90% (related to the base material)

• Short welding times (depending on the wire diameter only a few seconds are required)

• Low requirements for the preparation of the wire ends (any unevenness and contamination in the joint have little effect on the process)

• High reproducibility of the welding parameters; optionally an effective monitoring and the regulation of the welding process is possible

• High dimensional accuracy of the welded wires due to the tight length tolerances

BALDESSERA is one of the pioneers of the flash butt welding technology — since 2019.