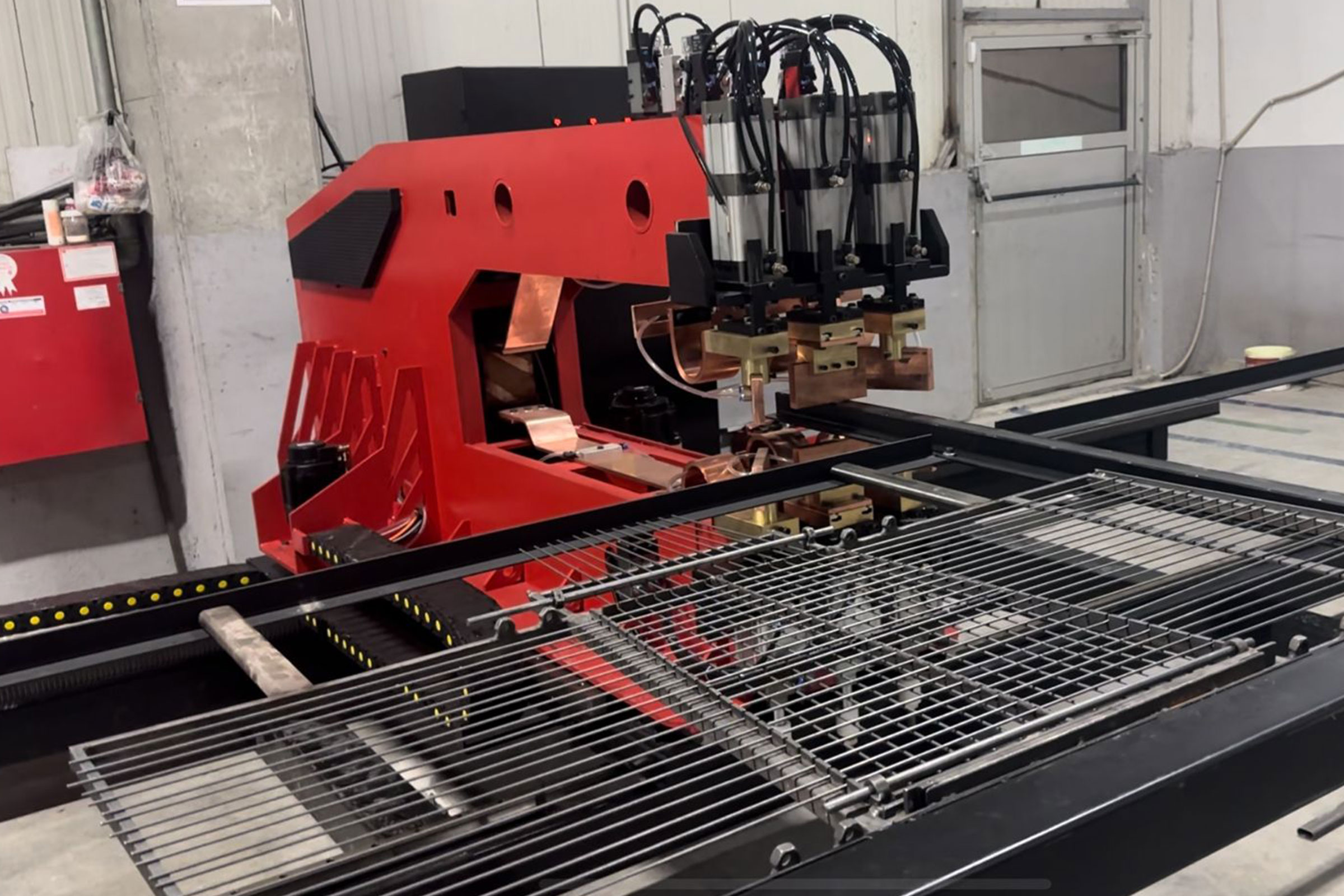

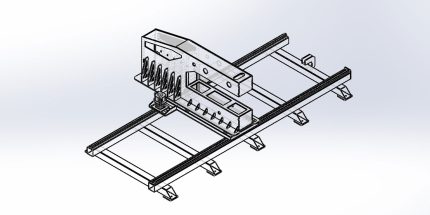

A projection-type spot welding machine is designed specifically for projection welding, which is a variation of resistance welding. In projection welding, metal sheets are joined using localized heat and pressure applied to specific contact points or projections on the work piece, rather than a continuous line or area. This method allows for more precise welds and is ideal for welding thicker materials or attaching components with small, raised projections (like bolts or nuts) to flat metal sheets.

Components and Features

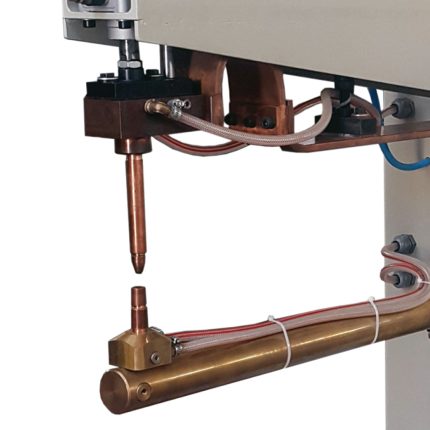

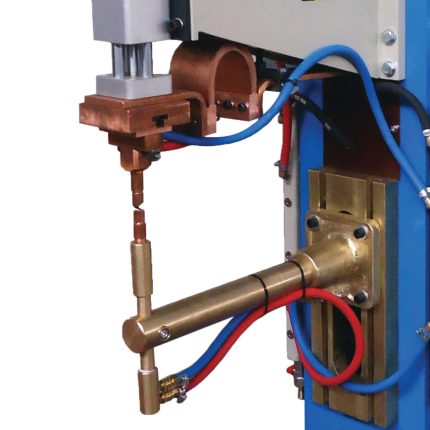

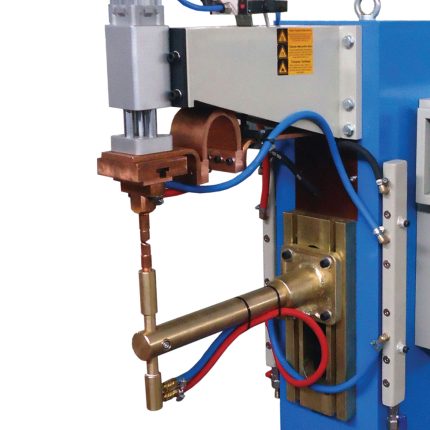

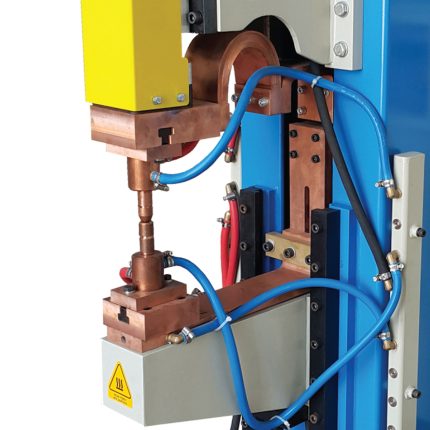

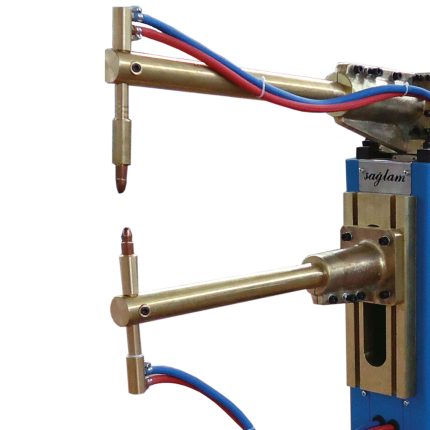

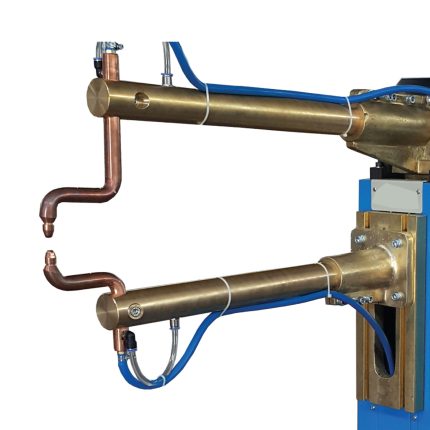

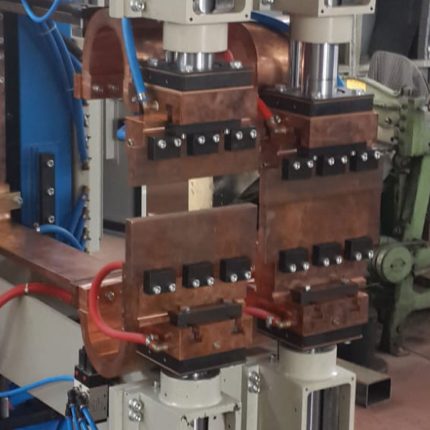

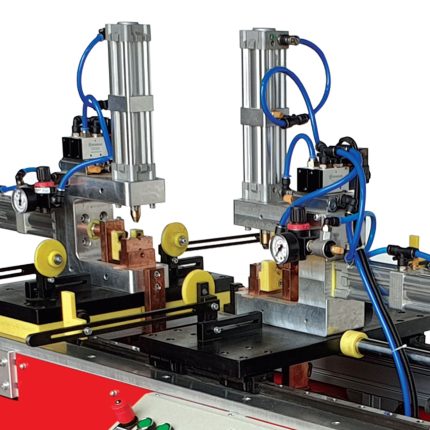

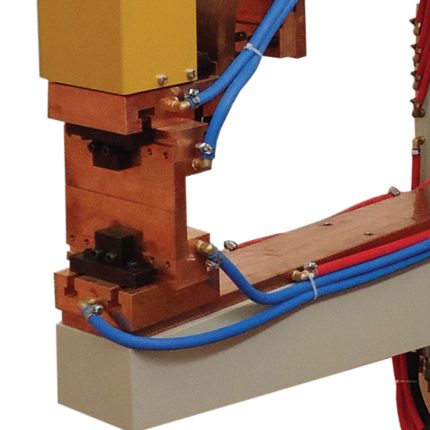

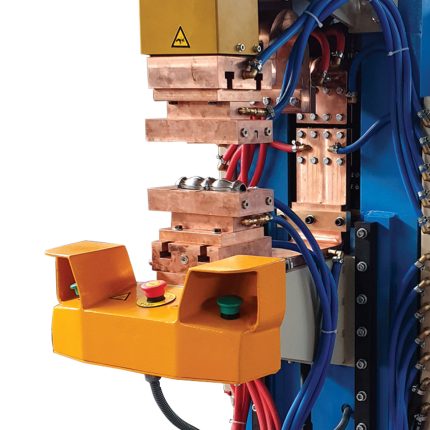

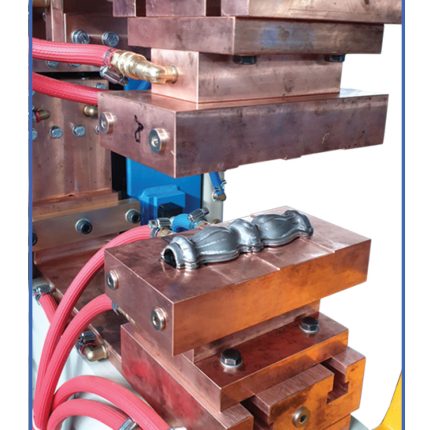

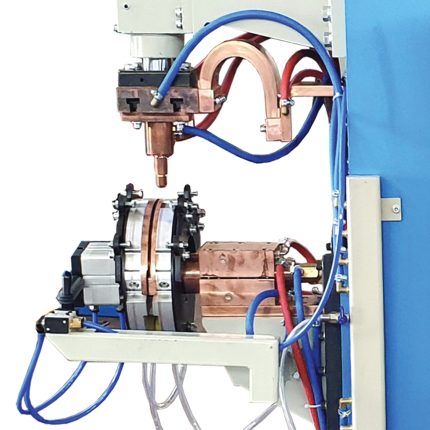

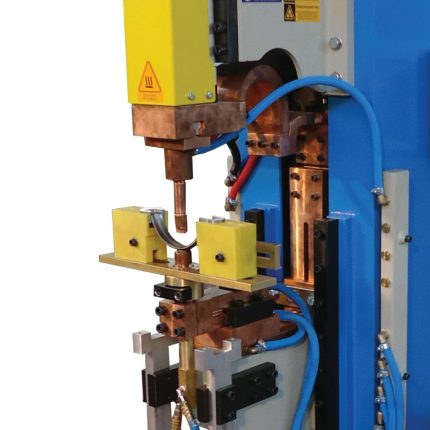

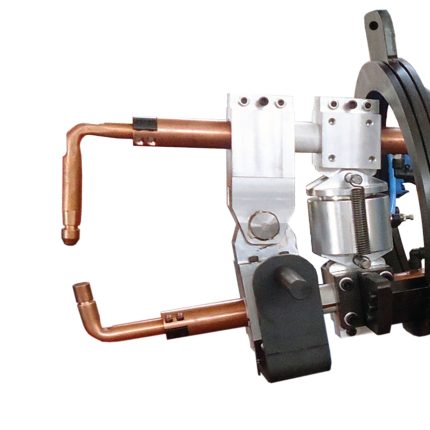

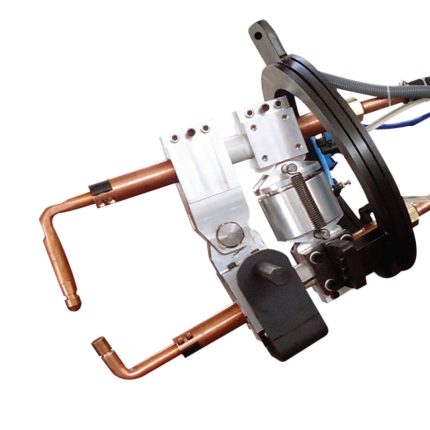

1. **Electrodes**: The electrodes are typically flat or specially shaped to ensure proper alignment and pressure at the projection points.

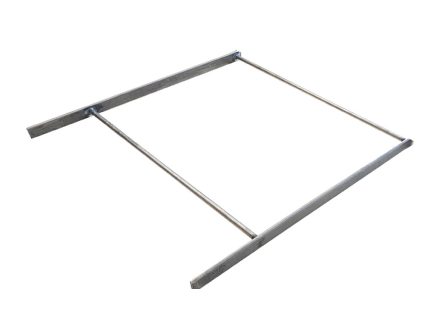

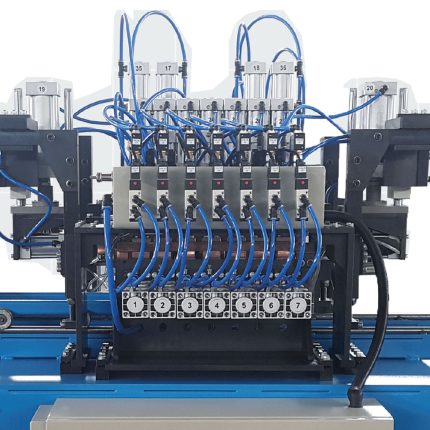

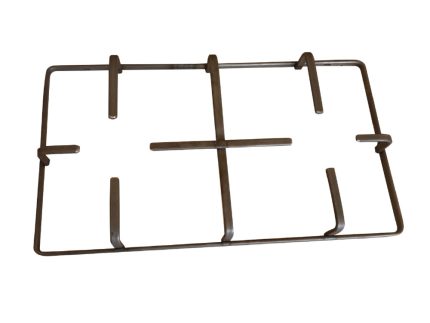

2. **Projections**: Small raised features on the workpieces, which focus current flow and heat precisely, creating localized weld spots.

3. **Pneumatic or Hydraulic Pressure Control**: For precise pressure application, essential in projection welding to avoid deforming the projections and ensuring consistent quality.

4. **Adjustable Welding Parameters**: Allow for precise control over welding current, time, and pressure, essential for accommodating various materials and projection designs.

Benefits

- **Consistent Weld Quality**: Controlled, focused heating on the projections minimizes the risk of distortion.

- **Increased Weld Strength**: High-pressure, focused heating can produce stronger weld joints, especially in thicker materials.

- **Flexibility**: Can be used for a wide range of applications, including automotive components, fasteners, brackets, and nuts.

Application

Projection-type spot welding machines are widely used in industries requiring durable, precise spot welds, such as:

- **Automotive Manufacturing**

- **Appliance Production**

- **Electrical and Electronic Components**

Would you like more details on specific models, manufacturers, or machine specifications?