A resistance seam welding machine is used to create continuous, leak-proof welds along the seams of overlapping or abutted metal sheets. This process is similar to spot welding, but instead of individual welds, it produces a series of overlapping weld nuggets, forming a continuous, airtight, and watertight joint. Seam welding is ideal for applications where a fluid-tight bond is needed, such as fuel tanks and food cans.

Components and Features

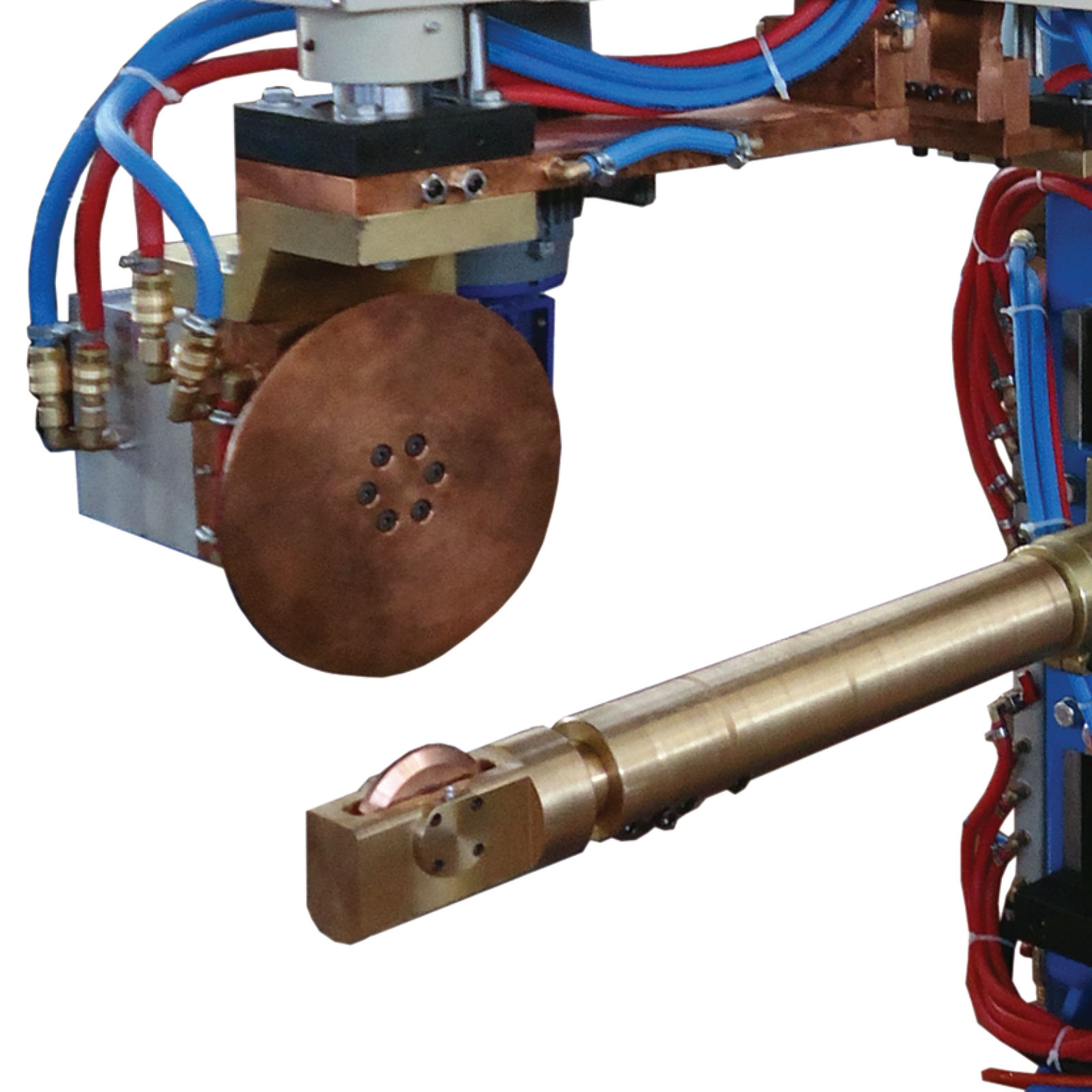

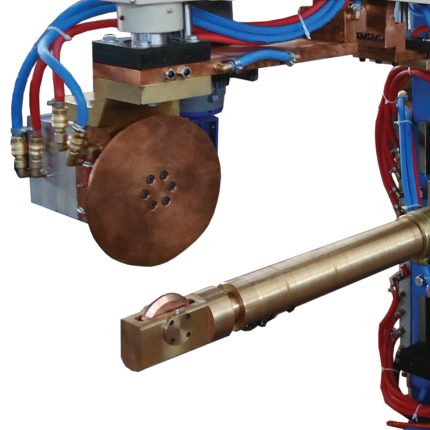

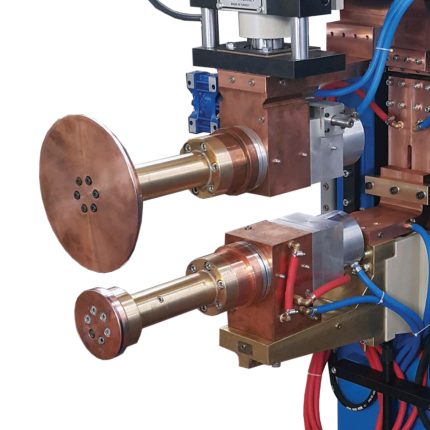

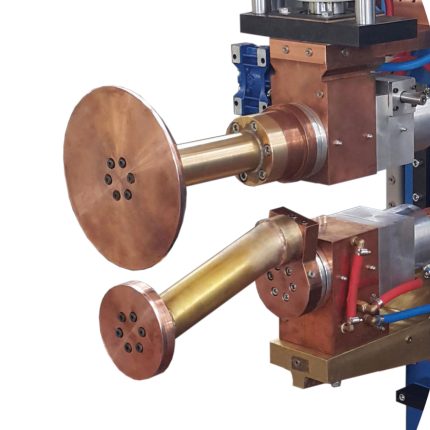

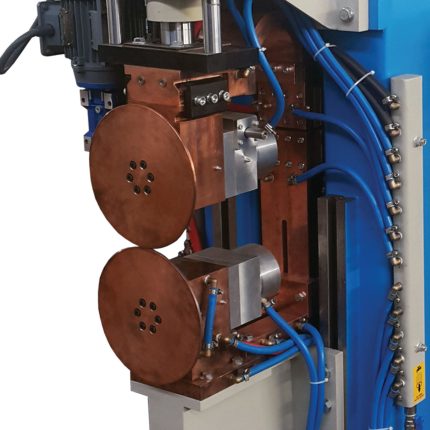

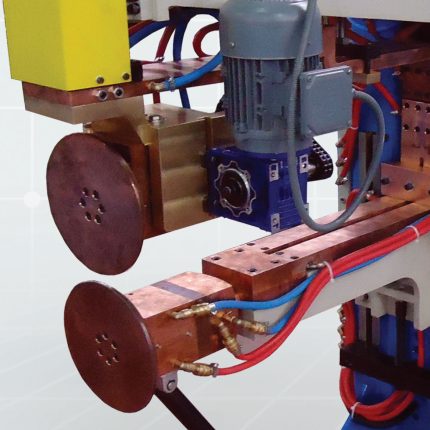

1. **Rotating Wheel Electrodes**: The machine uses two rotating wheels, rather than stationary electrodes, to press the sheets together and apply current along the seam.

2. **Welding Transformer**: Provides a controlled electrical current that generates heat at the interface of the sheets as the wheels roll along the seam.

3. **Force Control System**: Ensures consistent pressure is applied through the wheels, which is critical for achieving uniform welds.

4. **Adjustable Welding Parameters**: Weld current, wheel speed, and pressure can be adjusted to accommodate different materials and thicknesses.

Process Variations

- **Intermittent Seam Welding**: Produces a series of weld nuggets with small gaps between them, useful for applications not requiring an airtight seal.

- **Continuous Seam Welding**: Overlapping welds along the entire seam to form a continuous, leak-proof joint.

Benefits

- **Strong, Airtight Seams**: Creates joints capable of withstanding pressure, making it ideal for liquid- or air-tight applications.

- **High Production Speed**: Rolling electrodes enable fast, continuous welding, increasing production efficiency.

- **Reduced Heat Affected Zone (HAZ)**: The process minimizes the HAZ, preserving material strength and reducing distortion.

Application

Resistance seam welding machines are widely used in industries that require continuous, durable, and fluid-tight seams, such as:

- **Automotive Manufacturing** (fuel tanks, exhaust pipes)

- **Food and Beverage Containers** (metal cans)

- **Appliances** (refrigerators, washing machines)

- **Aerospace and HVAC Ducting**

Would you like more details on machine models, specifications, or manufacturers for resistance seam welding?